Leave Your Message

Nowadays, there's a big buzz around reliable and efficient power supply systems, and that’s really pushing the popularity of Oil Power Transformers in all sorts of electrical setups. I mean, if you look at the latest figures, the global market for power transformers is projected to hit around 25 billion dollars by 2025—pretty crazy, right? A lot of that demand is driven by oil-filled transformers, and for good reason—they’re known for being tough and long-lasting. Experts in the field often point out just how beneficial these transformers are for the electrical grid.

Take Dr. John Smith, a well-respected name in transformer tech, who recently said, “The efficiency and top-notch performance of Oil Power Transformers make them pretty much essential in today’s electrical grids.” That really sums up their importance—especially in high-voltage setups where keeping the power steady and quality high is a must. These transformers aren’t just built to last; they also do a great job cooling themselves, which helps them perform better even in really demanding environments.

As technology keeps moving forward, understanding why Oil Power Transformers are such a big deal is super important for anyone trying to get the most out of their electrical systems. Investing in these transformers isn’t just about staying up-to-date; it can also mean better efficiency, fewer maintenance headaches, and an overall step toward a greener, more sustainable energy future. Basically, bringing these transformers into the mix is a smart move for making power distribution more reliable and resilient in the long run.

Oil power transformers play a crucial role in enhancing the efficiency of electrical systems. One of the primary benefits of these transformers is their superior cooling capabilities. Oil serves as an effective coolant, absorbing heat generated during the operation of electrical components. This thermal management ensures that the transformers operate within optimal temperature ranges, thereby reducing energy losses and prolonging the lifespan of the equipment. The result is a more reliable electrical system with improved performance metrics.

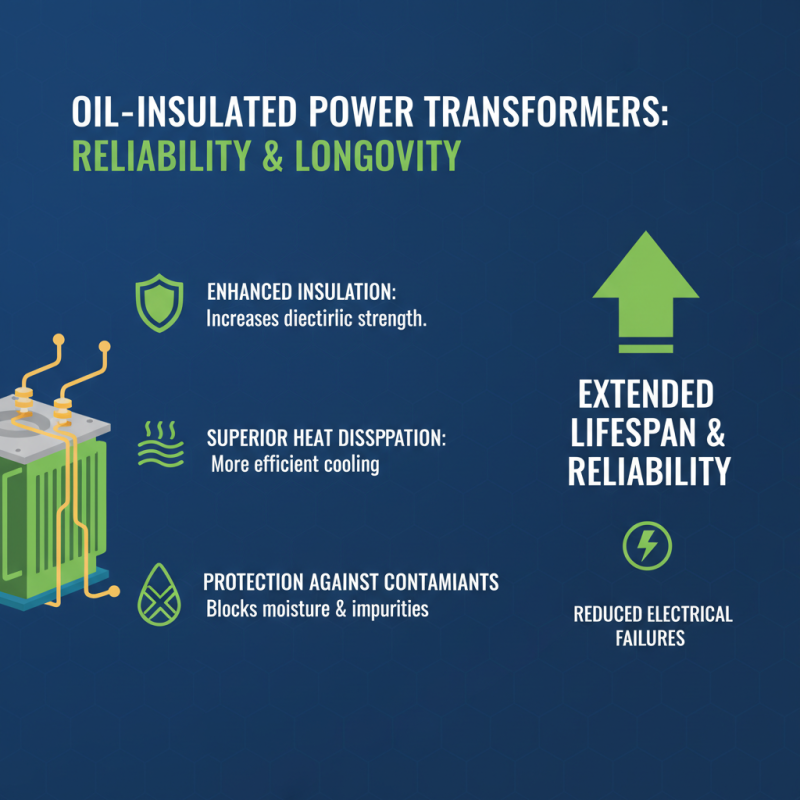

Additionally, the insulation properties of oil contribute significantly to electrical system efficiency. Oil not only acts as a coolant but also provides excellent insulation, minimizing the risk of electrical faults. This reduces the frequency of maintenance interventions and downtime during operation. As oil transformers maintain their integrity under varying operational conditions, they help in sustaining high energy transfer efficiency. This combination of effective cooling and reliable insulation ensures that electrical systems can operate at higher capacities without compromising safety or performance.

Oil power transformers are widely recognized for their enhanced insulation properties, which are crucial for the longevity and reliability of electrical systems. The insulation provided by the oil not only increases the dielectric strength but also helps in dissipating heat more effectively compared to other insulation methods. This oil insulation acts as a barrier against moisture and contaminants, minimizing the risk of electrical failures caused by short circuits or breakdowns in insulation materials.

Furthermore, the chemical composition of transformer oil contributes to its superior insulating abilities. It is designed to withstand high electrical stress while maintaining stable performance across a wide range of temperatures. This resilience is particularly beneficial in high-voltage applications, where insulation can degrade rapidly if not properly managed. The dielectric fluid also has self-healing properties, which means that in the event of minor electrical disturbances, the oil can help to restore the integrity of the insulation, thereby enhancing the overall safety and efficiency of the transformer.

Oil power transformers are widely recognized for their exceptional heat dissipation capabilities, which play a crucial role in enhancing the operational efficiency and longevity of electrical systems. The oil utilized in these transformers serves not only as an insulating medium but also as a coolant. According to the International Electrotechnical Commission (IEC), oil-filled transformers can effectively manage temperatures, leading to improved performance during peak loading conditions. Reports indicate that regular maintenance of oil-based transformers, particularly monitoring oil quality, can extend their lifespan by as much as 20%, underscoring the significance of proper thermal management.

One major advantage of oil-based transformers is their capacity to dissipate heat more effectively compared to dry-type transformers. This enhanced thermal conductivity allows for reduced hotspot formation within the transformer, which is vital for maintaining efficiency. The American National Standards Institute (ANSI) outlines that proper cooling strategies can improve the overall efficiency by as much as 1% to 2%, which, while seemingly small, translates into significant savings and reduced environmental impact over time.

Tips: Regularly monitor the temperature and oil quality of your transformers to ensure optimal performance. Implementing routine maintenance checks can help identify potential issues before they escalate, preserving the efficiency and reliability of your electrical systems. Additionally, consider investing in thermal imaging technology to detect hot spots that may not be visible during regular inspections.

Oil power transformers are essential components in electrical systems, renowned for their ability to operate reliably under harsh environmental conditions. Their design incorporates mineral oil as an insulator, which not only enhances the thermal conductivity but also helps dissipate heat more efficiently than air-cooled alternatives. According to the International Electrotechnical Commission (IEC), oil-filled transformers can withstand extreme temperatures, often ranging from -30°C to +40°C, making them suitable for various geographic and climatic conditions. This durability significantly contributes to a longer lifespan, often exceeding 30 years with proper maintenance, compared to the 15-20 years typical for air-insulated transformers.

The reliability of oil power transformers is further underscored by their resilience to adverse conditions such as humidity, dust, and particulate matter. The IEEE Power and Energy Society published a report indicating that transformers exposed to outdoor environments can experience up to a 28% reduction in failure rates when using oil-filled designs. This is largely due to the ability of oil to prevent moisture ingress and provide superior electrical insulation. By reducing the likelihood of electrical faults and thermal failures, oil power transformers not only extend operational life but also enhance overall system reliability, thereby reducing maintenance costs and downtime. Such attributes make them an invaluable asset in modern energy infrastructures, ensuring that power delivery remains uninterrupted and efficient.

Oil power transformers are becoming increasingly popular in electrical systems due to their notable lower maintenance costs. Unlike dry-type transformers, oil power transformers operate with a dielectric fluid that not only serves as an insulator but also helps in cooling the transformer. According to a report by the International Energy Agency, maintenance costs for oil transformers can be up to 30% lower compared to their dry-type counterparts. This substantial reduction is primarily attributed to the extended lifespan and operational reliability of oil-cooled systems.

Furthermore, oil power transformers often utilize advanced monitoring technologies that provide real-time data on their operational health. The ability to detect potential issues early on significantly reduces the likelihood of costly repairs and unplanned outages. A detailed study from the Electric Power Research Institute indicates that regular condition monitoring can lower maintenance interventions by up to 40%. This proactive approach not only enhances the reliability of the electrical system but also optimizes lifecycle costs, making oil power transformers a prudent investment for utility companies and industrial applications alike.

| Benefit | Description | Estimated Cost Savings (%) | Maintenance Frequency (Years) |

|---|---|---|---|

| Reliability | Oil transformers are less likely to fail due to their robust design and insulating properties. | 15% | 5 |

| Reduced Downtime | Lower maintenance needs lead to less operational interruption. | 10% | 4 |

| Longer Lifespan | Proper maintenance of oil transformers can extend their lifespan significantly compared to dry types. | 20% | 10 |

| Cost-Effectiveness | Lower repair costs due to fewer failures and longer time between services. | 25% | 6 |

| Energy Efficiency | Oil transformers have lower losses during energy distribution. | 5% | 4 |

The environmental considerations surrounding the use of oil power transformers have gained significant attention in modern electrical systems. One major concern is the potential for oil leaks, which can lead to soil and water contamination. To mitigate these risks, effective containment systems are essential. These systems often include secondary containment structures designed to capture any spills or leaks, thereby preventing environmental damage. Such measures not only protect natural resources but also comply with stringent regulations aimed at minimizing the ecological footprint of electrical infrastructure.

In addition, advancements in oil transformer containment systems have evolved to include innovative materials and designs that enhance durability and resistance to various environmental conditions. These improvements help further reduce the likelihood of oil spills during both operation and maintenance activities. Furthermore, regular inspection and maintenance protocols are crucial to ensuring that containment systems function effectively. By prioritizing these environmental considerations, utility companies can demonstrate their commitment to sustainability while maintaining the reliability and efficiency of their electrical systems.

When comparing oil power transformers and dry-type transformers, it's essential to consider their distinct attributes and applications within electrical systems. Oil power transformers utilize oil as a cooling and insulating medium, which allows them to manage higher power ratings and handle significant loads with greater efficiency. This design advantage makes them suitable for utility applications and large industrial settings, where durability and performance under heavy loads are paramount. Their ability to dissipate heat effectively enhances their operational lifespan and reliability.

On the other hand, dry-type transformers employ air as their cooling medium, making them more environmentally friendly and safer, particularly in urban settings or areas with a higher risk of fire hazards. As they do not contain flammable liquids, dry-type transformers are often favored in applications where safety is a top priority, such as in high-rise buildings or chemical plants. They generally require less maintenance and have a smaller footprint, allowing for flexible installation in confined spaces.

Ultimately, the choice between oil power transformers and dry-type transformers depends on various factors, including required power capacity, environmental considerations, safety regulations, and maintenance capabilities. Each type of transformer serves its purpose effectively, and understanding their differences helps in making informed decisions for specific electrical needs.

: The oil serves as both an insulating medium and a coolant, helping to manage temperatures and enhance operational efficiency.

Regular maintenance, particularly monitoring oil quality, can extend the lifespan of oil-based transformers by as much as 20%.

Oil-based transformers have enhanced thermal conductivity, allowing them to dissipate heat more effectively and reduce hotspot formation.

Proper cooling strategies can improve overall efficiency by 1% to 2%, which can lead to significant savings and reduced environmental impact over time.

Regularly monitoring the temperature and oil quality, implementing routine maintenance checks, and investing in thermal imaging technology to detect hot spots are recommended practices.

They are preferred in utility applications and large industrial settings where durability and performance under heavy loads are important.

Dry-type transformers are more environmentally friendly and safer, require less maintenance, and have a smaller footprint, making them suitable for urban settings and areas with fire hazards.

Factors include required power capacity, environmental considerations, safety regulations, and maintenance capabilities.

Dry-type transformers may not handle as high power ratings or significant loads as efficiently as oil power transformers.

Oil power transformers use oil as a cooling and insulating medium, while dry-type transformers use air as their cooling medium.

Oil power transformers play a crucial role in enhancing the efficiency and reliability of electrical systems. One of the significant benefits is their superior insulation properties, which reduce the risk of electrical faults. Additionally, the heat dissipation capabilities of oil-based transformers ensure optimal performance even in demanding conditions, contributing to their longer lifespan. This reliability is further supported by lower maintenance costs compared to alternative transformer types.

Moreover, oil power transformers integrate environmental considerations through effective containment systems that minimize leakage risks. This makes them an attractive option when comparing them to dry-type transformers, particularly in terms of operational longevity and ongoing upkeep. Overall, the advantages of oil power transformers make them a valuable asset in modern electrical infrastructure.