Leave Your Message

In the ever-changing world of energy, picking the right power transformer isn’t just a technical choice — it’s pretty much essential for keeping the lights on and making sure everything runs smoothly. The International Energy Agency (IEA) recently highlighted that global electricity demand is expected to jump by about 30% by 2040. That’s a massive push for better infrastructure, especially those big transformers. As industry expert Dr. Emily Roberts puts it, “Getting the right Power Transformer can be the difference between quick growth and ending up with operational headaches.” Balancing power generation and consumption isn’t straightforward, so it’s super important to carefully think through all the factors when choosing one.

For folks in electrical engineering, understanding technical specs, the environment where the transformer will be used, and the load requirements is absolutely crucial. Plus, a recent report on the global power transformer market shows that demand for smarter, more advanced transformers is expected to grow at about 6.5% annually over the next few years — thanks largely to urbanization and new tech pushing forward. All this just goes to show that investing some time and resources into finding the right transformer isn’t optional — it’s key to making power systems reliable and budget-friendly in the long run.

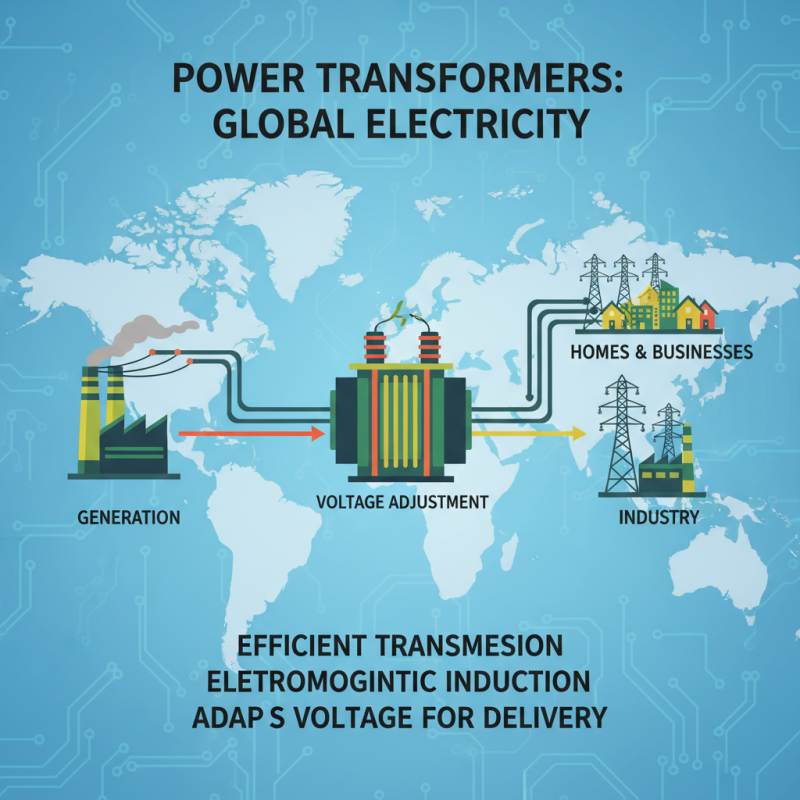

Power transformers play a crucial role in the global electrical grid by facilitating the efficient transmission and distribution of electricity. Understanding their function is essential for anyone involved in electrical engineering or power management. At their core, power transformers transfer electrical energy between circuits through electromagnetic induction, allowing for voltage levels to be adjusted according to specific needs. This adaptability is vital, as it ensures that electricity generated at power plants can be effectively delivered to homes and businesses, thereby supporting everyday activities.

The importance of selecting the right transformer cannot be overstated. Each application has unique requirements, such as voltage levels, capacity, and environmental conditions, all of which influence transformer performance and longevity. A well-chosen transformer ensures optimal energy efficiency, reduces losses, and enhances system reliability. Additionally, understanding the basics of transformer components, such as core materials and winding configurations, helps in making informed decisions that can lead to improved operational outcomes in power systems. By grounding your knowledge of power transformers, you can better align your choices with the demands of modern electrical infrastructure.

When it comes to selecting the right power transformer for your needs, understanding your power requirements is crucial. The first step in this process is to accurately assess the power demands of your applications. Consider the voltage and current levels necessary for your equipment to function optimally. Remember that both continuous and peak loads should be evaluated to ensure that the transformer can handle variations in power demand without risking damage or inefficiency.

As you begin to narrow down your options, keep in mind that the transformer’s power rating should exceed your calculated requirements. This additional capacity not only accommodates fluctuations in demand but also extends the lifespan of the transformer itself. Moreover, consider the environment where the transformer will be installed. Factors such as temperature, humidity, and exposure to contaminants can affect performance, so selecting a transformer suited for your specific conditions is vital.

To further streamline your selection process, you can implement a few practical tips. First, consult with a power systems expert who can provide insights based on your particular scenario. Second, prioritize transformers that offer flexibility in configuration, which allows for future modifications as your power needs evolve. Lastly, look into energy efficiency ratings, as more efficient transformers can lead to significant cost savings and reduced environmental impact over time. By following these guidelines, you can ensure that you select a power transformer tailored to your unique requirements.

This chart illustrates essential parameters to consider when selecting a power transformer based on power requirements. Each factor represented (Transformer Size, Load, Efficiency, Voltage Level, and Frequency) plays a critical role in ensuring optimal performance and reliability of power transformers.

When selecting a power transformer, understanding the different types available on the market is crucial to ensure optimal performance and efficiency. Primarily, transformers can be categorized into two main types: step-up transformers and step-down transformers. Step-up transformers increase voltage from the primary to the secondary coil, making them essential for power generation and transmission applications where voltage needs to be raised to minimize losses over distance. Conversely, step-down transformers decrease voltage levels, which are vital for distributing electricity to homes and businesses.

Beyond the basic types, there are specialized transformers such as isolation transformers, which are used to separate different parts of an electrical system for safety, and autotransformers, which are typically more compact and efficient for applications where the voltage difference is small. According to a 2022 report by the International Energy Agency, the demand for efficient transformer technologies is projected to grow by 4.5% annually due to an increasing focus on renewable energy integration and grid modernization.

Furthermore, with advancements in materials and design, the latest power transformers are designed to offer enhanced operational efficiencies and reduced carbon footprints. As organizations look to upgrade their infrastructure, understanding these various transformer types can lead to more informed decisions that align with both technical requirements and sustainability goals.

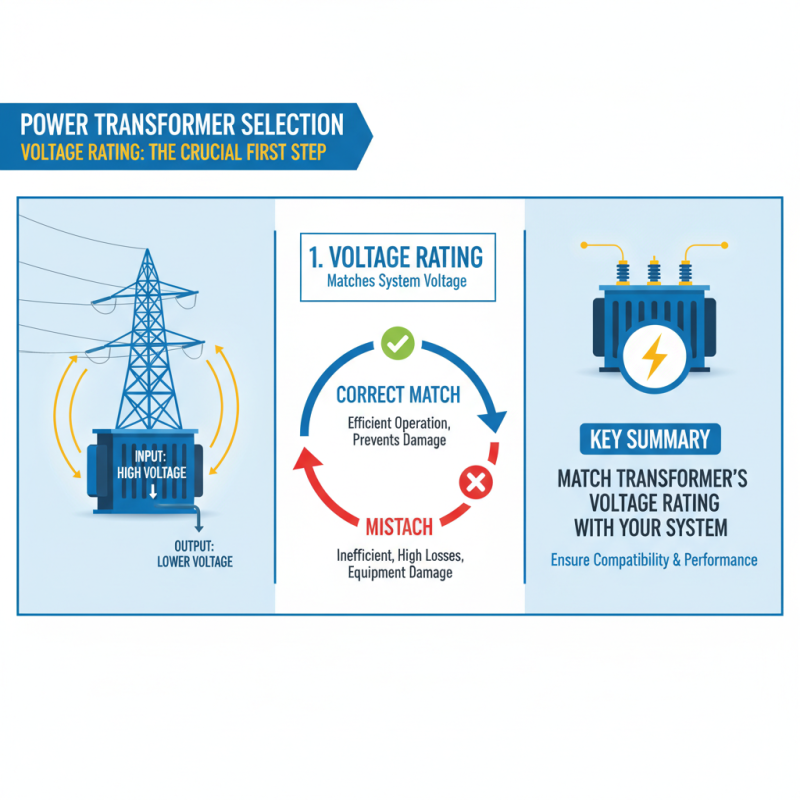

When selecting a power transformer, evaluating transformer ratings is crucial to ensure it meets your specific needs. The first factor to consider is voltage rating. This indicates the transformer's capacity to handle high voltage input while providing a lower voltage output for usage. It's essential to match the transformer’s voltage rating with your system voltage to prevent potential overloading or underperformance. A mismatch can lead to inefficient operation, increased losses, and may even cause equipment damage.

Another critical aspect to consider is the capacity rating, often expressed in kVA (kilovolt-amperes). The capacity represents the maximum load the transformer can support without overheating. Selecting a transformer with the appropriate capacity ensures that it can adequately handle the peak demands of your electrical system without exceeding its limits. Additionally, efficiency factors should not be overlooked; a higher efficiency transformer will convert more electrical power into usable output, resulting in lower operational costs and reduced energy waste. Balancing these ratings will lead to more reliable and efficient power distribution systems tailored to your requirements.

When selecting a power transformer, one of the most critical aspects to consider is the environmental factors that can significantly impact its performance and longevity. According to the International Electrotechnical Commission (IEC), transformers may experience performance degradation due to temperature fluctuations, humidity, or corrosive atmospheres. For instance, temperature extremes beyond the manufacturer's specified limits can lead to insulation breakdown, reducing the operational lifespan of the transformer. Reports from industry analyses suggest that for every 10°C increase in operational temperature, the insulation life expectancy halves, making thermal considerations paramount.

Moisture and humidity levels also play a crucial role in transformer efficiency. The IEEE (Institute of Electrical and Electronics Engineers) indicates that a humidity level consistently above 60% can lead to increased risk of internal condensation, which adversely affects insulation and can cause short circuits. Furthermore, environmental pollutants, such as dust, salt, and industrial chemicals, can act as catalysts for corrosion. It has been noted in several studies that transformers installed in coastal areas may experience a higher rate of material degradation due to salt spray, underscoring the need for careful location assessment during the selection process. Therefore, understanding and evaluating these environmental factors can substantially enhance the reliability and efficiency of power transformers, ensuring they meet specific operational demands.

When selecting a power transformer, adherence to industry standards and regulations is paramount. Power transformers must comply with specifications outlined by organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC). These standards ensure safety, efficiency, and reliability in electrical systems. A detailed report by the Electric Power Research Institute (EPRI) highlights that transformers that meet these guidelines can exhibit up to a 15% increase in operational efficiency, significantly reducing long-term energy costs.

Tip: Always verify that the transformer you consider purchasing is certified to meet applicable regulatory standards. This not only mitigates risks associated with equipment failure but also ensures that the transformer operates optimally within your specific application.

Compliance also plays a critical role in environmental sustainability. According to a 2022 industry report, transformers manufactured in accordance with the latest energy efficiency standards can reduce greenhouse gas emissions by 20% compared to older units. This reduction is vital as industries move towards greener practices.

Tip: Evaluate the life cycle assessment (LCA) data provided by manufacturers to make an informed choice about the environmental impact of the transformers. Making selections based on compliance and energy efficiency not only contributes to regulatory adherence but also promotes responsible energy usage.

| Tip | Description | Importance of Compliance | Related Standards |

|---|---|---|---|

| 1. Define Power Needs | Assess your total power requirement including voltage and current. | Ensures transformer chosen can handle the load. | IEC 60076 |

| 2. Consider Environment | Take into account temperature, humidity, and other environmental factors. | Compliance to environmental standards ensures reliability. | ISO 14001 |

| 3. Evaluate Efficiency | Look for transformers with high energy efficiency ratings. | Reduced energy loss helps in cost savings. | IEEE 802.3 |

| 4. Check Voltage Regulation | Understand how voltage variations are managed. | Maintains performance under fluctuating loads. | NEMA ST 20 |

| 5. Assess Size and Footprint | Ensure the transformer fits in the allocated space. | Compliance with space and safety regulations. | OSHA Standards |

| 6. Review Noise Levels | Consider sound output during operation. | Noise regulations need to be adhered to for safety. | ANSI S12.60 |

| 7. Investigate Cooling Methods | Choose appropriate cooling systems based on application. | Compliance with thermal efficiency standards. | UL 506 |

| 8. Check for Maintenance Requirements | Understand the maintenance schedule and requirements. | Ensures long-term compliance with operational standards. | IEEE C57.94 |

| 9. Verify Reliability and Longevity | Assess warranties and expected lifespan. | Reduces downtime and ensures adherence to uptime standards. | IEC 60529 |

| 10. Consult with Experts | Seek professional advice for complex requirements. | Expertise ensures compliance with current regulations. | Various Industry-Specific Standards |

When it comes to purchasing a power transformer, striking the right balance between cost and quality is critical. According to a report by the International Energy Agency, the global demand for efficient power transformers is projected to grow by 5% annually through 2025, reflecting their essential role in modern power systems. However, selecting a transformer solely based on the lowest price can lead to higher operational costs in the long term. Investing in quality equipment can minimize downtime, reduce maintenance expenses, and enhance overall system reliability.

Budget considerations should also take into account the transformer’s efficiency ratings and lifecycle costs. Data from the Electric Power Research Institute indicates that the use of energy-efficient transformers can yield savings of up to 30% in energy costs. Additionally, factors such as installation expenses and compatibility with existing infrastructure should be factored into the overall budget. As you evaluate different options, it's crucial to compare not only the upfront costs but also the long-term benefits associated with a higher quality product. Such a comprehensive approach will ensure that your investment pays off in both performance and efficiency.

Three-phase oil immersed distribution transformers are essential components in the modern electrical infrastructure, designed to provide reliable voltage transformation for both outdoor and indoor applications. The S13 model series stands out with a rated voltage range of 2.5 to 40.5kV, making it suitable for various industrial and commercial needs. These transformers comply with IEC 60076-1 and EN 50588-1 standards, ensuring high performance and safety in operation.

The benefits of using oil immersed transformers include excellent thermal management due to the oil's natural cooling properties, which facilitates efficient operation and longevity. These transformers are built for resilience, capable of withstanding harsh environmental conditions while maintaining operational efficiency. The two-year warranty provided reflects the confidence in the durability and reliability of the product, making it a smart investment for stakeholders looking to enhance their energy distribution systems. Additionally, the versatility in application allows for seamless integration into diverse electrical setups, reinforcing their role as a backbone in electrical distribution.

: Assessing power requirements is crucial to ensure that the transformer can handle both continuous and peak loads without risking damage or inefficiency.

The transformer’s power rating should exceed calculated power requirements to accommodate fluctuations in demand and extend its lifespan.

Environmental factors such as temperature, humidity, and exposure to contaminants can degrade performance and reduce the longevity of transformers.

Performance degradation occurs when temperature exceeds specified limits; for every 10°C increase, the insulation life expectancy halves.

Humidity levels consistently above 60% increase the risk of internal condensation, adversely affecting insulation and possibly causing short circuits.

Common types include step-up transformers, which increase voltage, and step-down transformers, which decrease voltage for distribution purposes.

Isolation transformers are used to separate different parts of an electrical system for enhanced safety.

A power systems expert can provide insights tailored to specific scenarios, ensuring optimal selection based on unique power requirements.

Energy-efficient transformers can lead to significant cost savings and a reduced environmental impact over time.

The installation environment, such as coastal areas with higher corrosion risks or areas with extreme temperatures, should be carefully assessed to ensure reliability and efficiency.

Choosing the right power transformer is crucial for ensuring efficient and reliable electrical performance. The article outlines essential tips that begin with understanding the basics of power transformers and their significance in various applications. It emphasizes the importance of accurately identifying power requirements, as this forms the foundation for optimal transformer selection.

Additionally, the article explores the different types of power transformers available in the market, guiding readers through evaluating important ratings such as voltage, capacity, and efficiency. Environmental factors that may impact transformer performance are discussed, along with the necessity of compliance with industry standards and regulations. Finally, budget considerations are highlighted, stressing the need to balance cost with quality for a successful purchase. Following these tips will lead to better decisions when selecting a power transformer to meet specific needs.